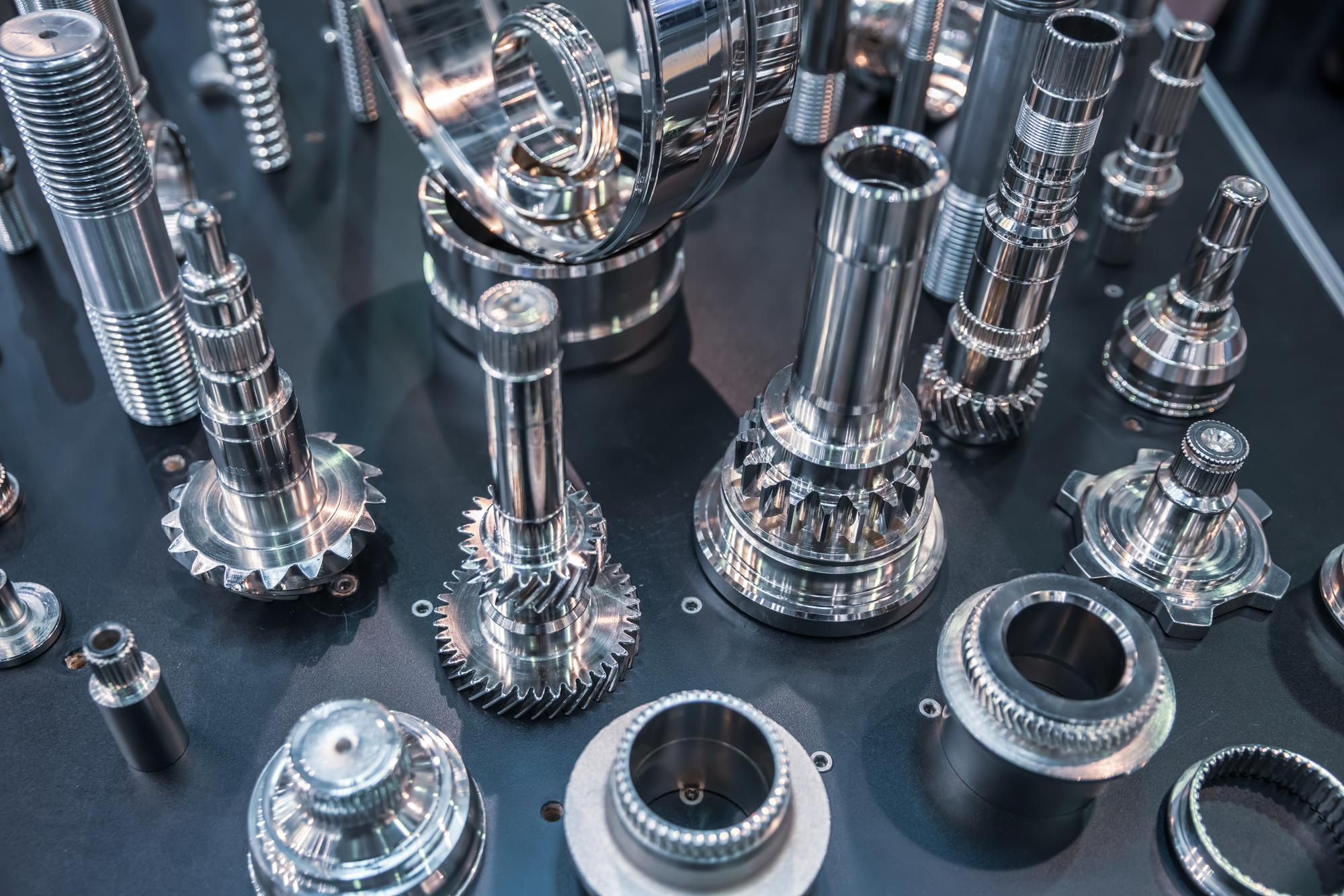

Introduction to Mechanical Springs

Springs are essential components in mechanical systems, designed to store and release energy or absorb shock by resisting force through elastic deformation. The versatility of springs is critical across various industries as they can be engineered in numerous configurations such as compression, tension, torsion, leaf, and disc springs to suit specific functions. For example, compression springs commonly support loads in industrial machinery, while the fine torsion springs play a pivotal role within precise timekeeping devices. Their significance lies in their ability to maintain system stability, manage forces efficiently, and enhance product longevity by mitigating the impact of mechanical stress.

Compression Springs

Compression springs are designed to operate with a compressive load, meaning they resist being compressed and return to their original length when the load is removed. These springs are generally cylindrical in shape and crafted from helically coiled wire. As force is applied to push the spring shorter, it pushes back against the load and can maintain strength over repeated cycles of compression and relaxation. A common example of where compression springs are utilized is within internal combustion engines; valve springs here ensure that engine valves close properly after opening. The spring’s ability to rebound efficiently after shortening is critical for maintaining the timing and operation of an engine’s moving parts.

Tension or Extension Springs

Tension springs, also known as extension springs, are helical wound coils designed to operate with a force that stretches the spring. Unlike compression springs which resist compressive forces and get shorter when a load is applied, tension springs work in the opposite manner: they store energy and exert a pulling force when extended. An everyday example of tension springs can be seen in garage door mechanisms. These springs balance the weight of the garage door as it opens and closes by extending and retracting, allowing for smooth and controlled movement. In practice, tension springs feature hooks or loops at their ends to attach them to other components and are critical in various applications where tensile strength is required.

Torsion Springs

Torsion springs operate on the principle of elasticity, designed to exert torque or rotary force. The mechanics behind these springs are based on their tightly wound coils that can store and release angular energy when twisted. As such, each coil serves as an individual storage mechanism for mechanical energy; once a load is applied, the torsion spring’s arms rotate about the central axis, delivering force to push or pull depending on the directionality of the application. A commonplace example of torsion springs at work is in clothespins, where the inherent tension maintains the pin’s grip, and in window shades, where they control the motion required to raise or lower the shade with consistent, smooth movements without sagging.

Leaf Springs

Leaf springs are a type of suspension component commonly used in vehicles, characterized by their multi-layered structure, each layer known as a leaf. These layers are bound together to act as a single unit that can flex under load while providing support and absorbing shocks. The construction typically consists of several long, narrow arcs of high-grade spring steel stacked with the longest leaf on top, progressively decreasing in length towards the bottom. This design allows for even distribution of weight and controlled flexibility. Leaf springs are particularly popular in heavy-duty applications such as trucks, vans, and SUVs due to their durability and ability to handle substantial loads over uneven terrain.

Coil Springs

Coil springs are fundamental mechanical components that store and release energy through elasticity, exhibiting a force when compressed or stretched. Characterized by their helical shape, coil springs are engineered from elastic materials to regulate motion or absorb shocks in various applications. In the realm of mattresses, they provide support and comfort by compressing under weight and returning to their original shape upon unloading. Meanwhile, in automotive suspensions, coil springs play a crucial role in maintaining vehicle stability, absorbing road irregularities to offer a smooth ride. Their widespread utilization stems from durability, consistent performance over numerous cycles, and versatility in fulfilling diverse functional requirements ranging from tension to torsion and compression.

Gas Springs

Gas springs are distinct from conventional metal coil springs, functioning not through physical compression and expansion, but by the pneumatics of compressed gas. Contained within a cylinder, a piston moves as gas is either added or released, allowing these springs to exert force or provide support. The operation relies on the principle that the pressure of the contained gas resists the external force applied to the piston, thereby creating a damping effect or maintaining a specific position. A common example of a gas spring in everyday use is the support mechanism found in adjustable office chairs, enabling smooth height alteration and cushioning during seating.

Specialized Types of Springs

Beyond the more common coil and torsion springs, there exist specialized types that serve unique applications due to their particular properties. For example, Belleville washers offer a type of spring action through their conical shape, which enables them to support high loads with small deflections; this feature is particularly useful in bolted assemblies to maintain tension under thermal changes or vibrations. Additionally, constant force springs are constructed from a strip of steel that rolls out and retracts in an even manner, making them excellent for providing consistent force in mechanisms like retractable reels, cable retrievers, or counterbalances in machinery parts. The precise operation of these springs demonstrates the diversity and innovation found within the category of specialized springs.

Factors That Influence Spring Selection

When choosing the appropriate type of spring for a given application, several critical factors come into play. The material composition is paramount as it dictates the spring’s strength, flexibility, corrosion resistance, and temperature tolerance – stainless steel, for instance, retains its properties in harsh conditions, whereas phosphor bronze may be favored for electrical conductivity. Load type, whether compressive or tensile, determines if coil springs, leaf springs, or torsion springs are deployed. Furthermore, environmental conditions such as extreme temperatures, chemical exposure, or presence of moisture must align with the chosen spring’s capabilities to avoid degradation over time. For example, in marine settings where saltwater corrosion is a concern, an Inconel spring would offer superior longevity compared to traditional carbon steel.

Maintenance and Lifespan of Different Types of Springs

To prolong the service life of various springs, it’s crucial to adhere to proper maintenance practices. Regular inspection to detect signs of wear, fatigue, or corrosion ensures early intervention and remedies. For example, lubrication reduces friction in compression and extension springs, preventing premature breakage. In torsion springs, maintaining appropriate torque levels and avoiding overloading preserves structural integrity. The specific application considerably influences a spring’s longevity – automotive suspension coils are subject to high-impact loads and variable temperatures demanding more rigorous attention compared to low-stress applications like pen springs. Ensuring that each type of spring is operated within its design limits can significantly extend its useful lifespan.

Q&A Section: Understanding Springs

In assessing the versatility of springs, the coil spring stands out due to its ability to effectively store and release energy in a multitude of applications, from automotive suspensions to mechanical pencils. The reliance on a single type of spring for all designs is impractical because each application demands specific attributes such as load capacity, space constraints, and environmental resilience; for instance, a torsion spring’s rotational force is ideal for clothespins while extension springs are essential for trampolines. Determining the size of a spring involves calculations based on the intended load, material properties, and required deflection which ensures that the spring can perform its function without premature failure. Over time and repeated use, springs may experience ‘springiness’ loss due to material fatigue or plastic deformation, often accelerated by extreme conditions like high-stress loads or corrosive environments.