Introduction to Non-Ferrous Metals

Non-ferrous metals are a group of materials distinguished by their lack of iron content, which differentiates them from ferrous metals that do contain iron. Unlike their ferrous counterparts, non-ferrous metals are not magnetic and are often more resistant to corrosion and lighter in weight, making them highly valuable in industries like aerospace where weight is critical. A classic example includes aluminum, known for its lightweight and rust resistance, utilized extensively in the construction of aircraft and automotive parts. These properties stem from the absence of iron, as it’s the reaction between iron and environmental factors such as water and oxygen that typically leads to rust in metals. By contrast, non-ferrous metals offer enhanced electrical conductivity, as seen in copper wiring used across various electronic applications, showcasing another facet of their wide-ranging utility.

Characteristics of Non-Ferrous Metals

Non-ferrous metals are characterized by a set of unique properties that differentiate them from their ferrous counterparts. A prominent feature is their corrosion resistance; metals like aluminum and copper form a protective oxide layer when exposed to the atmosphere, inhibiting further corrosion—a trait highly valuable for construction materials or in naval architecture. When it comes to electrical conductivity, non-ferrous metals outshine most others, with copper being a fundamental component due to its excellent ability to conduct electricity, making it indispensable for wiring and electronics. In terms of weight, these metals often present a lighter alternative to iron and steel—aluminum is approximately one-third the weight of steel, offering advantages for aircraft design due to the strength-to-weight ratio. Another significant characteristic is their non-magnetic nature, which allows use in electronic shielding and high-endurance rotating machinery applications where magnetic interference can be detrimental. These inherent qualities of non-ferrous metals pave the way for innovation across numerous industries, bringing forth advancements in technology and engineering.

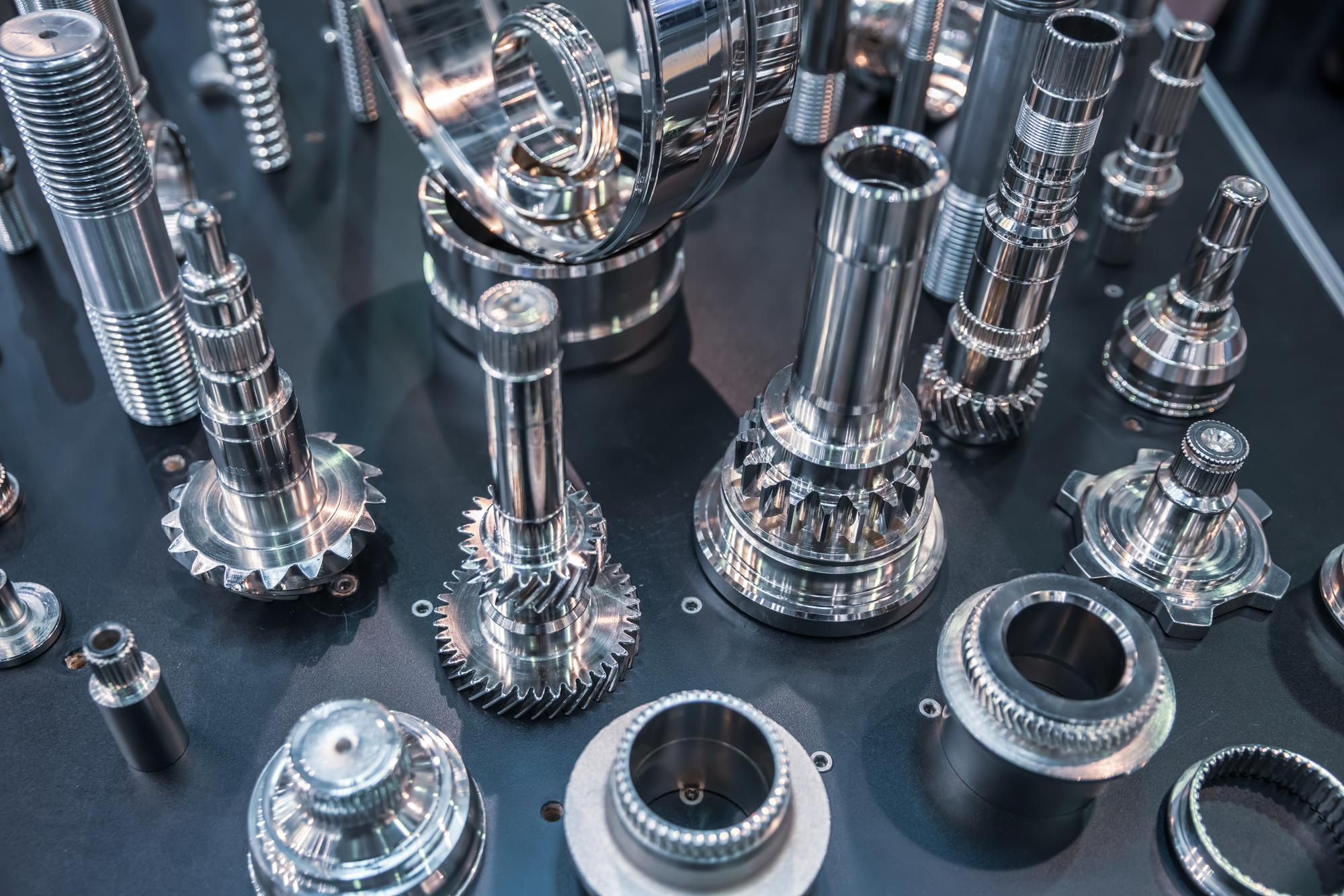

Common Types of Non-Ferrous Metals and Their Properties

Diving into the realm of non-ferrous metals, we find materials critical to a myriad of industries due to their distinct properties. Aluminum stands out for its remarkable combination of light weight and high thermal as well as electrical conductivity, making it an ideal candidate for aerospace applications and high-voltage overhead power lines. Copper is distinctly renowned for its unparalleled conductive capabilities concerning electricity, which positions it as a staple in the electrical industry for wiring, motors, and other components where efficient energy transfer is key. In stark contrast to these lighter metals, Lead presents itself as a dense metal known specifically for its soundproofing abilities and resistance against corrosion; it plays a pivotal role in areas such as radiation shielding and battery production. Zinc, while not as widely discussed, serves a crucial purpose through galvanization – the process of preventing rust by coating other metals, significantly extending the lifespan of structures like bridges and vehicles exposed to harsh environments.

Applications of Non-Ferrous Metals in Various Industries

In the construction industry, non-ferrous metals like aluminum and copper are widely used for roofing and infrastructure due to their resistance to rust and light weight. The automotive industry favors these materials for performance parts, as they decrease overall vehicle mass thereby improving fuel efficiency and dynamics. Within electronics, non-ferrous metals serve a critical role; copper is particularly prevalent for its superior electrical conductivity, which is instrumental in producing reliable wiring and components. Moreover, specialized alloys find their place in medical diagnostic equipment, providing both durability and precise functionality essential for getting accurate results. Each sector benefits from specific attributes of non-ferrous metals, whether it’s their non-magnetic properties, corrosion resistance or thermal conductivity, underscoring their versatility and indispensability across industries.

Development of New Alloys for Specialized Purposes

In the dynamic field of materials science, non-ferrous metals are continually manipulated to create new alloys tailored for specific functions that meet modern technological demands. Scientists and engineers innovate by altering metallic compositions, introducing other elements to enhance characteristics such as strength, ductility, conductivity, and resistance to corrosion. For example, beryllium-copper alloys gain prominence in applications requiring high electrical conductivity combined with substantial strength. Similarly, titanium alloys are revered for their unparalleled strength-to-weight ratios suited for aerospace and medical prosthetics. These innovations not only push the boundaries of what is possible with non-ferrous metals but also pave the way for advancements across various industries.

Challenges in the Use of Non-Ferrous Metals

The utilization of non-ferrous metals comes with numerous challenges, notably when considering cost factors versus availability. Scarce elements such as indium or gallium can hike production costs and limit widespread application due to their limited abundance and complex extraction processes. In tandem, technical limitations emerge while operating under extreme environments; for instance, certain non-ferrous metals may become brittle or lose structural integrity at high temperatures or in corrosive surroundings. Additionally, environmental considerations are paramount as mining and refining these materials often lead to ecological disruption. Strategies aimed at recycling and more sustainable extraction methods must be developed to mitigate adverse environmental impacts.

Future Trends in Non-Ferrous Metal Usage

The trajectory for non-ferrous metal consumption is slated to ascend, propelled by burgeoning sectors such as electric vehicles (EVs), which are forecasted to multiply their demand for metals like lithium, nickel, and cobalt critical for battery production. Concurrently, the pivot towards renewable energy systems marks a significant opportunity for increased utilization of non-ferrous metals; aluminum, copper, and others play essential roles in solar panels, wind turbines, and energy storage solutions. Anchoring these developments are ongoing research advancements, poised to yield novel alloys with enhanced properties and more efficient recycling methods that will further streamline the incorporation of non-ferrous metals into future technologies.